Enhancing Bonding Strength: The Role of Petroleum Resin in Adhesives and Sealants Formulations

2024-03-18

Adhesives and sealants are integral components in a wide array of industries, providing essential bonding and sealing functionalities in various applications. Behind the scenes of these versatile products lies a key ingredient: petroleum resin. In this blog, we'll explore how petroleum resin contributes to the formulation of adhesives and sealants, facilitating strong bonds, durable seals, and reliable performance in diverse settings.

Understanding Petroleum Resin:

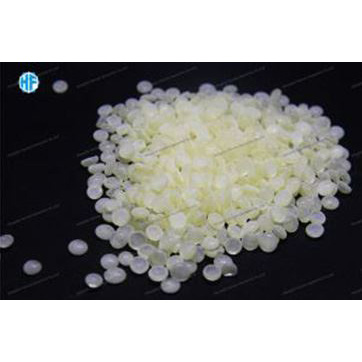

Petroleum resin is a synthetic resin derived from petroleum feedstocks through polymerization processes. It boasts a unique combination of properties, including solubility, viscosity, and tackiness, making it an ideal candidate for enhancing the performance of adhesives and sealants.

Enhancing Adhesive Strength:

1. Tackifying Agent:

Petroleum resin acts as a tackifying agent in adhesives formulations, improving their adhesive strength and bonding properties. By increasing the tackiness of the adhesive, petroleum resin enhances its ability to form strong bonds with various substrates, including metals, plastics, and wood.

2. Improved Cohesion:

The incorporation of petroleum resin enhances the cohesion of the adhesive, increasing its internal strength and durability. This results in adhesives with improved resistance to shear, peel, and impact forces, ensuring long-lasting bonds even under challenging conditions.

Facilitating Formulation Versatility:

1. Solubility and Compatibility:

Petroleum resin exhibits excellent solubility in a wide range of solvents, allowing for easy incorporation into adhesive formulations. Its compatibility with other adhesive components ensures uniform dispersion and homogeneous blends, enhancing formulation stability and performance.

2. Viscosity Control:

Control over viscosity is crucial in adhesive formulations to achieve optimal application properties. Petroleum resin offers flexibility in viscosity adjustment, allowing formulators to tailor adhesives for specific application methods, substrates, and environmental conditions.

Diverse Applications:

1. Construction and Building Materials:

Petroleum resin-based adhesives play a vital role in construction applications, bonding materials such as wood, metal, and concrete in building and infrastructure projects. They provide strong, durable bonds that withstand structural loads, vibrations, and weathering.

2. Automotive and Transportation:

Adhesives formulated with petroleum resin are widely used in automotive assembly and repair, bonding components such as body panels, trim, and glass. These adhesives offer superior bonding strength, corrosion resistance, and vibration damping properties.

Sealants and Protective Coatings:

1. Sealing and Weatherproofing:

Petroleum resin-based sealants provide effective sealing and weatherproofing solutions for joints, gaps, and seams in construction and automotive applications. They form durable seals that resist moisture, air infiltration, and environmental degradation, ensuring long-term protection and structural integrity.

2. Corrosion Protection:

Sealants and coatings formulated with petroleum resin offer corrosion protection for metal surfaces exposed to harsh environments, such as marine, industrial, and automotive applications. They provide a barrier against moisture, chemicals, and corrosive agents, extending the lifespan of metal structures and components.

Conclusion:

Petroleum resin plays a crucial role in formulating adhesives and sealants, providing essential properties that enhance bonding strength, formulation versatility, and application performance. Whether in construction, automotive, or industrial applications, petroleum resin-based adhesives and sealants offer reliable solutions for bonding, sealing, and protection, driving efficiency, durability, and innovation in modern manufacturing processes. With its unique contributions, petroleum resin continues to shape the landscape of adhesives and sealants formulations, enabling strong bonds and durable seals that stand the test of time.